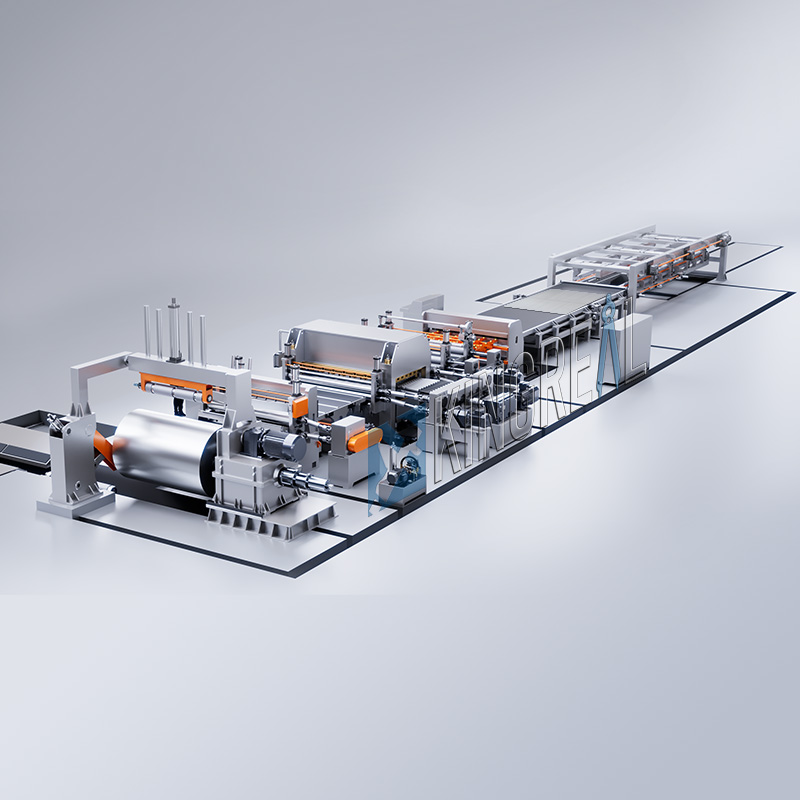

Selamat datang untuk memilih pemotongan kelajuan tinggi Kingreal Steel ke penyelesaian garis panjang. yang akan memberi anda potongan panjang dengan kelajuan80m/min atau lebih tinggi, yang digunakan untuk proses pengeluaran memotong bahan dan ketebalan gegelung yang berlainan ke dalam lebar yang ditentukan oleh pelanggan dan menyusunnya.

KingReal Steel Slitter adalah pembekal profesional Cut to Long Line di China, dengan pasukan teknikal profesional, keupayaan pengeluaran dan keupayaan selepas jualan. 2025, dalam bidang pemotongan ke penyelidikan mesin panjang danPembangunan juga telah membuat kejayaan bersejarahdalam rawatan gegelungjulat ketebalan melebihi 25mm, iaitu untuk pemotongan kelajuan tinggi ke kapasiti pembuatan mesin panjang, kapasiti pemprosesan dan kawalan ketepatan mempunyai keperluan yang sangat tinggi.

Slitter Steel KingReal telah berjaya mencapai jangka panjang dalam pemotongan berkelajuan tinggi hingga garis panjang dan kerjasama yang stabil dengan Rusia, Arab Saudi, Emiriah Arab Bersatu, Turki dan Indonesia.

Semasa memastikan pengeluaran berkelajuan tinggi, KingReal Steel Slitter komited untuk menyediakan pelanggan dengan kepelbagaian kelajuan tinggi ke garis panjang untuk memenuhi keperluan ketepatan mereka yang semakin menuntut:

1. Pengendalian stok yang tepat untuk pemotongan berkelajuan tinggi hingga mesin panjang

KingReal Steel Slitter Potong kelajuan tinggi ke garisan panjang dilengkapi dengan perapi dengan pencincang sekerap dan penghantar sekerap. Reka bentuk ini memastikan bahawa stok dipotong kepada lebar tepat sebelum ricih, dengan itu meningkatkan kecekapan dan ketepatan pemprosesan berikutnya dan mengurangkan sisa bahan secara berkesan semasa proses pengeluaran.

2. Teknologi pemotongan-ke-panjang kelajuan tinggi untuk pemotongan berkelajuan tinggi hingga garis panjang

KingReal Steel Slitter Potong kelajuan tinggi ke mesin panjang menggunakan ricih mekanikal kelajuan yang berubah-ubah, yang bukan sahaja meningkatkan pengeluaran tetapi juga mengekalkan kestabilan pemotongan pada kelajuan tinggi. KingReal Steel Slitter Potongan kelajuan tinggi ke mesin panjang menghasilkan stok berkualiti tinggi dengan produktiviti yang lebih tinggi, memenuhi keperluan kualiti yang ketat dari pelbagai industri.

3. Reka bentuk ricih berimpak rendah untuk potongan kelajuan tinggi hingga garis panjang

Untuk memanjangkan hayat pemotongan berkelajuan tinggi ke mesin panjang, KingReal Steel Slitter telah merancang kelajuan slaid ricih yang rendah. Reka bentuk ini berkesan mengurangkan kesan, bunyi bising, dan getaran pada bilah ricih semasa operasi, mengurangkan potongan kelajuan tinggi hingga memakai garis panjang. Ini bukan sahaja meningkatkan kecekapan pengeluaran tetapi juga menjimatkan kos penyelenggaraan pelanggan dan penggantian bilah.

4. Kos Penyelenggaraan Ekonomi untuk Potongan Berkelajuan Tinggi hingga Lama Panjang

Pemotongan kelajuan tinggi KingReal Steel ke pemacu kelajuan pembolehubah mesin panjang menghilangkan keperluan untuk melibatkan klac atau brek setiap kali bahan dipotong, mengurangkan klac mahal dan penyelenggaraan brek.

5. Keupayaan pemotongan ketepatan untuk pemotongan kelajuan tinggi hingga garis panjang

Pemotongan kelajuan tinggi KingReal Steel ke mesin panjang menawarkan ketepatan pemotongan ± 0.005 inci (0.13 mm), menjadikannya sesuai untuk bahan-bahan dengan keperluan permukaan yang ketat, seperti keluli tahan karat, aluminium, dan kemasan pra-lot. Selain itu, pemotongan kelajuan tinggi keluli KingReal Steel ke ciri-ciri mesin panjang, slit, dan keupayaan meratakan ketepatan, dan mampu memproses bentuk trapezoid dan paralelogram.

6. Teknologi aci bilah ketepatan tinggi untuk memotong kelajuan tinggi hingga garis panjang

Pemotongan kelajuan tinggi KingReal Steel ke mesin panjang mencapai ricih ketepatan tinggi logam lembaran menggunakan galas aci bilah ketepatan tinggi. Teknologi ini bukan sahaja meningkatkan ketepatan pemotongan tetapi juga meningkatkan kestabilan mesin keseluruhan.

|

|

Potongan kelajuan tinggi ke garisan panjang mempunyai tempat yang penting dalam pemprosesan logam, memotong logam gegelung hingga panjang yang tepat untuk menjadi logam lembaran yang boleh digunakan secara langsung dalam aplikasi sekunder, yang melayani pelbagai industri seperti automotif, aeroangkasa, pertanian, pembinaan, HVAC, peralatan rumah, tenaga, dan industri lain dengan panjang logam lembaran yang disesuaikan dengan keperluan khusus.

|

|

Tawaran KINGREAL Mesin Cut To Length With Fly Shear, yang berkelajuan sehingga 80M/Min, boleh mendapat lebih banyak faedah pengeluaran untuk pelanggan dalam keluaran potongan logam kepada panjang.

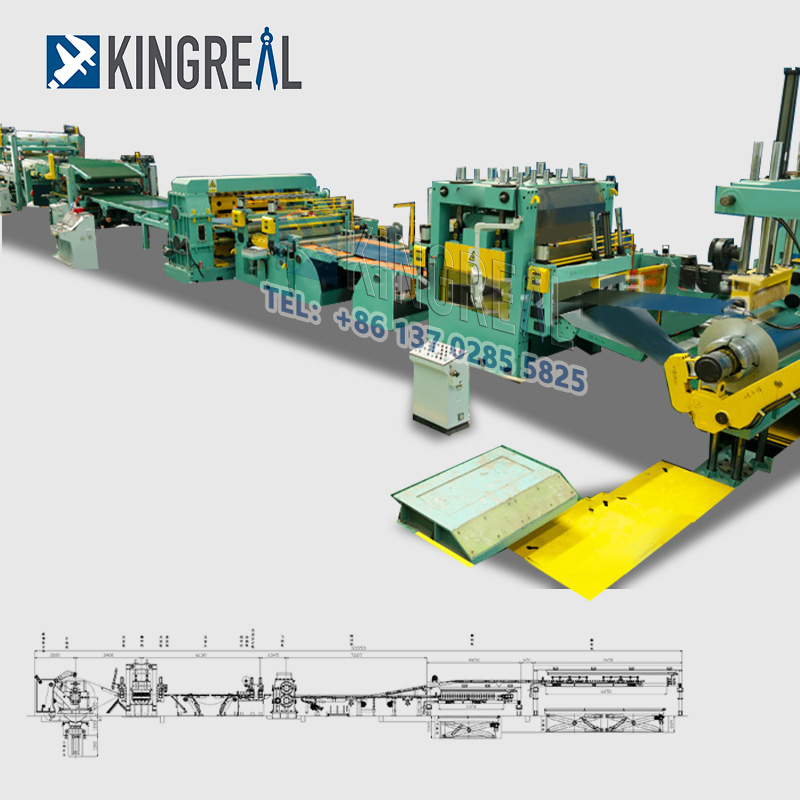

KingReal Steel Slitter telah berada dalam bidang garis ricih yang dipotong-ke-panjang selama lebih dari 20 tahun, dan mempunyai pasukan teknikal profesional untuk mengawal kualiti dari reka bentuk lukisan, pembuatan komponen mesin, inovasi konfigurasi, ujian dan pentauliahan barisan pengeluaran. Dengan keupayaan reka bentuk bebas, kami dapat menyediakan penyelesaian yang disesuaikan mengikut keperluan pelanggan kami.

Slitter slitter KingReal mempunyai banyak pengalaman projek dalam barisan pengeluaran yang dipotong, menurut keperluan pengeluaran sebenar pelanggan, pengeluaran tiga jenis gegelung tinggi, sederhana dan ekonomi yang dipotong ke garis panjang, dan lebih daripada sedozen negara dan wilayah telah mencapai kerjasama jangka panjang dan stabil dengan pelanggan.

- Pra-jualan: Lukisan reka bentuk dan menyesuaikan pemotongan ke program mesin panjang mengikut keperluan pelanggan;

- Dalam jualan: Pastikan kualiti pengeluaran mesin, sediakan ujian ujian ke garisan panjang untuk memeriksa ketepatan garis pengeluaran yang berjalan;

- Perkhidmatan selepas jualan: Susun jurutera untuk membimbing dan mengajar pemasangan di kilang-kilang pelanggan.

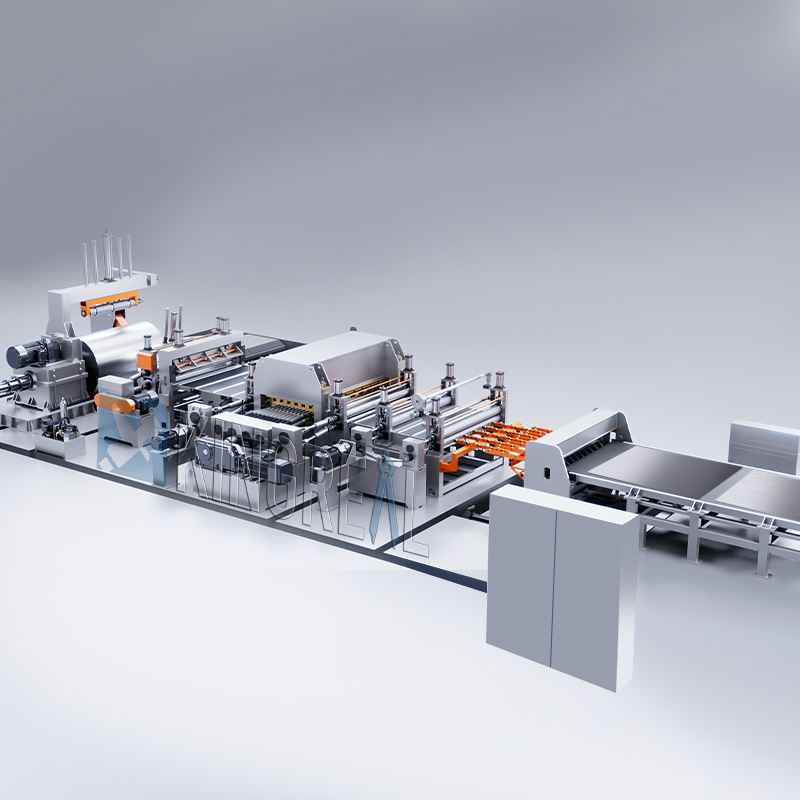

Garis ricih cut-to-panjang ricih terbang adalah garis pengeluaran automatik untuk pemprosesan lembaran logam. Ia boleh melengkapkan proses ricih ketepatan tinggi dan berkelajuan tinggi semasa operasi berterusan lembaran. Ia digunakan secara meluas dalam industri pemprosesan logam keluli dan bukan ferus.

1/ ricih segerak dinamik

Gegelung gegelung ricih terbang ke bilah mesin panjang melengkapkan ricih apabila lembaran bergerak, dan kelajuan mendatar bilah ricih disegerakkan dengan kelajuan lembaran (ralat dikawal dalam ± 0.8mm), mengelakkan kerugian kecekapan yang disebabkan oleh downtime.

Mekanisme pelarasan 2/ panjang

Hubungan berkadar antara kelajuan gelendong dan kelajuan pemakanan diselaraskan melalui kotak gear kelajuan berubah -ubah atau penghantaran yang berterusan.

3/ Kawalan Pintar

PLC atau penukar frekuensi (seperti siri GD350) digunakan untuk merealisasikan komunikasi bas, menyimpan pelbagai parameter proses dan menyesuaikan mesin pemotongan gegelung keluli dalam masa nyata.

4/ penjimatan tenaga dan reka bentuk yang cekap

Operasi yang berterusan Permulaan terbang ricih menjimatkan tenaga 1/3-1/2 berbanding dengan model tradisional, dan pemotongan keluli ke kelajuan garis panjang dapat mencapai 100m/min, yang sesuai untuk kepingan dengan ketebalan 0.3-6mm

Potongan ricih tetap ke garisan panjang mempunyai fungsi berhenti suapan pada panjang pratetap. Apabila panjang set dicapai, potong ricih tetap ke garisan panjang secara automatik berhenti, merapikan seksyen bahan sebelum dimulakan semula untuk memberi makan bahagian seterusnya garis yang perlu meluruskan dan memotong.

1/ Reka bentuk struktur mudah untuk dipotong ricih tetap ke garis panjang

Potongan ricih tetap ke garis panjang mempunyai struktur yang agak mudah dan mudah dioperasikan. Ciri ini membolehkan pemula untuk cepat menguasai operasinya selepas sesi latihan ringkas. Struktur yang dipermudahkan bukan sahaja mengurangkan kerosakan tetapi juga memudahkan penyelenggaraan rutin.

2/ Sesuai untuk pengeluaran berskala kecil

Walaupun potong ricih tetap ke garisan panjang dapat mencapai kelajuan 50m/min, ia tidak secepat kaedah ricih kecekapan tinggi yang lain. Oleh itu, pemotongan ricih tetap ke garisan panjang sangat sesuai untuk operasi pengeluaran yang lebih kecil. Bagi syarikat yang tidak memerlukan pengeluaran berskala besar, pemotongan ricih tetap ke garis panjang dapat memenuhi keperluan pengeluaran harian mereka, mengelakkan sisa sumber yang berkaitan dengan peralatan yang lebih efisien.

3/ Kesesuaian untuk kecekapan pengeluaran

Oleh kerana pemotongan ricih tetap ke garisan panjang mempunyai kelajuan maksimum 50m/min, ia sangat sesuai untuk pelanggan yang tidak mempunyai keperluan kecekapan pengeluaran yang tinggi. Fabrik kecil atau permulaan sering mencari penyelesaian pengeluaran yang kos efektif dan cekap. Dalam kes sedemikian, potongan ricih tetap ke garisan panjang memberikan kapasiti pemotongan yang mencukupi tanpa meletakkan tekanan yang berlebihan pada proses pengeluaran.

4/ Sesuai untuk pelanggan dengan belanjawan terhad

Oleh kerana kelajuan yang lebih rendah dan reka bentuk yang mudah, potong ricih tetap ke garisan panjang memerlukan spesifikasi dan prestasi komponen yang agak rendah. Ini mengurangkan kerumitan teknikal dalam pembuatan dan reka bentuk, mengakibatkan harga yang agak berpatutan. Oleh itu, pemotongan ricih tetap ke garisan panjang adalah pilihan yang ideal untuk pelanggan dengan belanjawan yang terhad, terutamanya pemula yang memasuki industri logam.

Swing Shearing Cut ke garisan panjang direka untuk memenuhi keperluan pelanggan untuk logam lembaran berbentuk adat. Melalui ayunan automatik gunting, swing ricih dipotong ke mesin panjang boleh dipotong pada pelbagai sudut, dengan berkesan memproses pelbagai bentuk seperti trapezoid, paralelogram, segitiga, dataran, dan segi empat tepat.

1/ memotong ke dalam bentuk yang berbeza

Swing shearing cut ke garisan panjang mampu memotong pelbagai bentuk. Dilengkapi dengan mekanisme pengapit panjang tetap, swing shearing dipotong ke mesin panjang dengan tepat memotong jalur bergerak ke dimensi yang dikehendaki. Proses ini memastikan bahawa setiap lembaran tepat disesuaikan dengan spesifikasi yang tepat pelanggan. Swing Shearing Cut to Long Machine menggabungkan beberapa teknologi yang inovatif, termasuk sistem penghapusan backlash yang terapung di mati, kunci mati cepat, dan perubahan alat yang cepat, meningkatkan kecekapan dan ketepatan ricih dengan ketara.

2/ Gerakan pemotongan swing untuk swing ricih dipotong ke garisan panjang

Potong ricih swing ke garisan panjang menggunakan gerakan pemotongan swing. Dengan mengoptimumkan laluan pemotongan, gerakan pemotongan swing memastikan kualiti ricih yang tinggi sambil meningkatkan kecekapan pengeluaran. Inovasi ini membolehkan pemotongan ricih swing ke garisan panjang untuk mengekalkan prestasi pemotongan peringkat tinggi merentasi pelbagai bahan, dari plat nipis hingga tebal.

3/ Swing Swing Speed High Cut ke garis panjang

Potongan ricih swing ke garisan panjang menawarkan kelajuan pengeluaran sehingga 80 m/min, memenuhi sepenuhnya tuntutan pengeluaran yang cekap. Kelajuan boleh diselaraskan secara fleksibel untuk memenuhi pelbagai persekitaran dan keperluan pengeluaran.

|

|

|